Hydraulic Line Pipes - ISMT Limited

Seamless Tubes for Hydraulic and Pneumatic Pressure Lines

ISMT manufactures cold-drawn precision seamless tubes for use in hydraulic pressure lines. These tubes are specially designed to withstand high static as well as dynamic loads and offer a long lasting, reliable solution.

All ISMT tubes embody over 20 years of experience in the manufacture of Seamless tubes. The quality of tubes that we manufacture for hydraulic pressure lines fully reflects experience.

Product Features

- Bright annealed scale-free surfaces

- Fully annealed for easy bending and flaring

- Consistent quality to ensure total reliability

- Manufactured from fully aluminum killed & vacuum degassed steel

- Ultra smooth inner surface for enhanced fluid flow.

Reliability Guaranteed

Hydraulic pressure lines are subject to high static as well as dynamic pressures and often to pressure shocks. The only way to guarantee that our tubes will perform without a single field failure is to control the entire production process. For this reason we start with producing all our steel in-house. We bring to bear over 20 years of experience in manufacturing high-grade Bearing steel to all our manufacturing processes and to all our steel products (we are among a few select manufacturers globally to be approved by SKF and FAG for the supply of Bearing steels).

We produce our steel through the Electric arc furnace route. The raw material mix is chosen and prepared carefully to ensure the highest standards of cleanliness. All heats are ladle refined and vacuum degassed before continuous casting and rolling. Right through the production process, we maintain full traceability of the material and a record of the tightly controlled process parameters. This ultra-clean steel forms the starting point for the manufacture of our tubes.

State Of The Art Equipment

The manufacture of precision seamless tubes is as much a matter of equipment as it is of experience and process technology. At ISMT, we believe in investing in the finest of equipment.For making seamless tubes we operate three Assel Mills, one PQF Mill, Pilger Mills, and Cold Draw Benches.

Our tube-mills are imported from Shloemann Mannesman in Germany and incorporate the best in technology. With regards to experience, our team is amongst the most technically qualified anywhere in the world - the tubes that we produce for use in Hydraulic and Pneumatic pressure lines reflect this experience.

Delivery Condition

| Designation | Symbol | Delivery Condition Description |

| Cold drawn / hard | +c(BK) | No heat treatment after the final cold drawing process |

| Cold drawn / soft | +LC(BKW) | After the final heat treatment there is a suitable drawing pass. |

| Cold drawn and stress Delivered | +SR(BKS) | After the final cold drawing process there is a stress relief heat t treatment in a controlled atmosphere |

| Annealed | +A(GBK) | After the final cold drawing process the tubes are annealed in a controlled atmosphere |

| Normal | +N(NBK) | After the final cold drawing process the tubes are normalized in a controlled atmosphere |

Standard Packing

Each tube is oiled, internally as well as externally, and then packed into hexagonal bundles. This ensures that the tubes are corrosion protected and that they retain their straightness during transport. Upon request, we can provide end caps and also wrap the bundles in LDPE sheets.

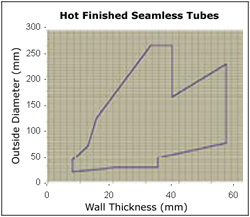

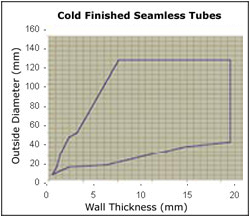

Customized Sizes

We produce seamless tubes with up to an outer diameter of sizes 273 mm (10 3/4 inches). In addition to the standard sizes, we can produce any customized size as per the graphs below.